Revolutionizing Asian Industry with AI Innovation

In the industrial powerhouses of China, Japan, and Taiwan, factories are harnessing artificial intelligence to redefine manufacturing. AI drives cutting-edge automation, elevates quality control, predicts maintenance with pinpoint accuracy, and optimizes processes to perfection.

The outcomes are transformative: lower costs, faster production, and better products. Led by industry giants, Asian factories aren’t just keeping up—they’re leading the way.

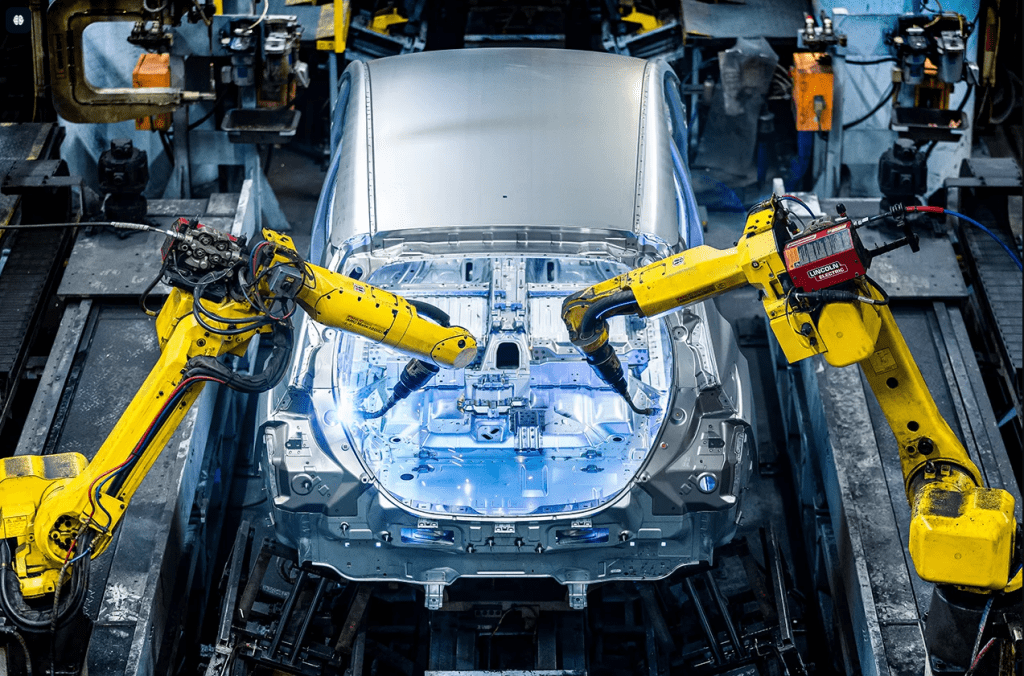

How AI Helped a Global Automotive Giant Achieve 30% Leaner Teams in EV Production

Problem Statement

The electric vehicle (EV) market is tough, and even big players face challenges. A leading Japan automaker saw a 30% sales drop in China in 2024, limited by a small EV lineup and extra factory capacity.

The mission was clear: cut fixed costs, streamline the workforce, and produce better products to stay a global leader.

AI Solution

This automaker used AI and automation to upgrade its cutting-edge EV factory. Self-driving carts (called AGVs) move smoothly around the factory, easily carrying huge 600 kg EV batteries—no heavy lifting needed.

AI-controlled welding machines adjust perfectly to create strong, flawless welds every time. Thanks to the factory’s smart setup, it now needs 30% fewer workers than older plants. This isn’t just an upgrade—it’s a huge leap forward for manufacturing.

Outcomes

The changes have made a massive difference. With 30% fewer workers, labor costs have dropped—but quality stays top-notch. Production is faster and smoother, helping the company launch an all-new electric SUV that could change the game.

Plus, the factory isn’t just building cars—it’s also a research hub. The lessons learned here about battery and suspension production will help the company stay ahead worldwide. This isn’t just a factory – it’s where the future of car-making begins.

Source:

This use case is based on a case study by Honda. For more details, please refer to the original case study Honda Replaces Workers With Robots And AI To Slash Costs At Chinese EV Plant

AI: The Engine Behind Asia’s Manufacturing Success

Asia’s factories aren’t just adopting AI—they’re redefining its potential. While labor challenges push automation, the region’s real competitive edge lies in how AI is deployed: cutting-edge tools that boost precision, scalability, and innovation.

For example, AI-powered quality control now detects defects faster than human eyes, while predictive maintenance cuts off downtime. Leading manufacturers aren’t just replacing workers; they’re augmenting human skills with AI to dominate global supply chains—like hitting 2040 targets for electric vehicles.

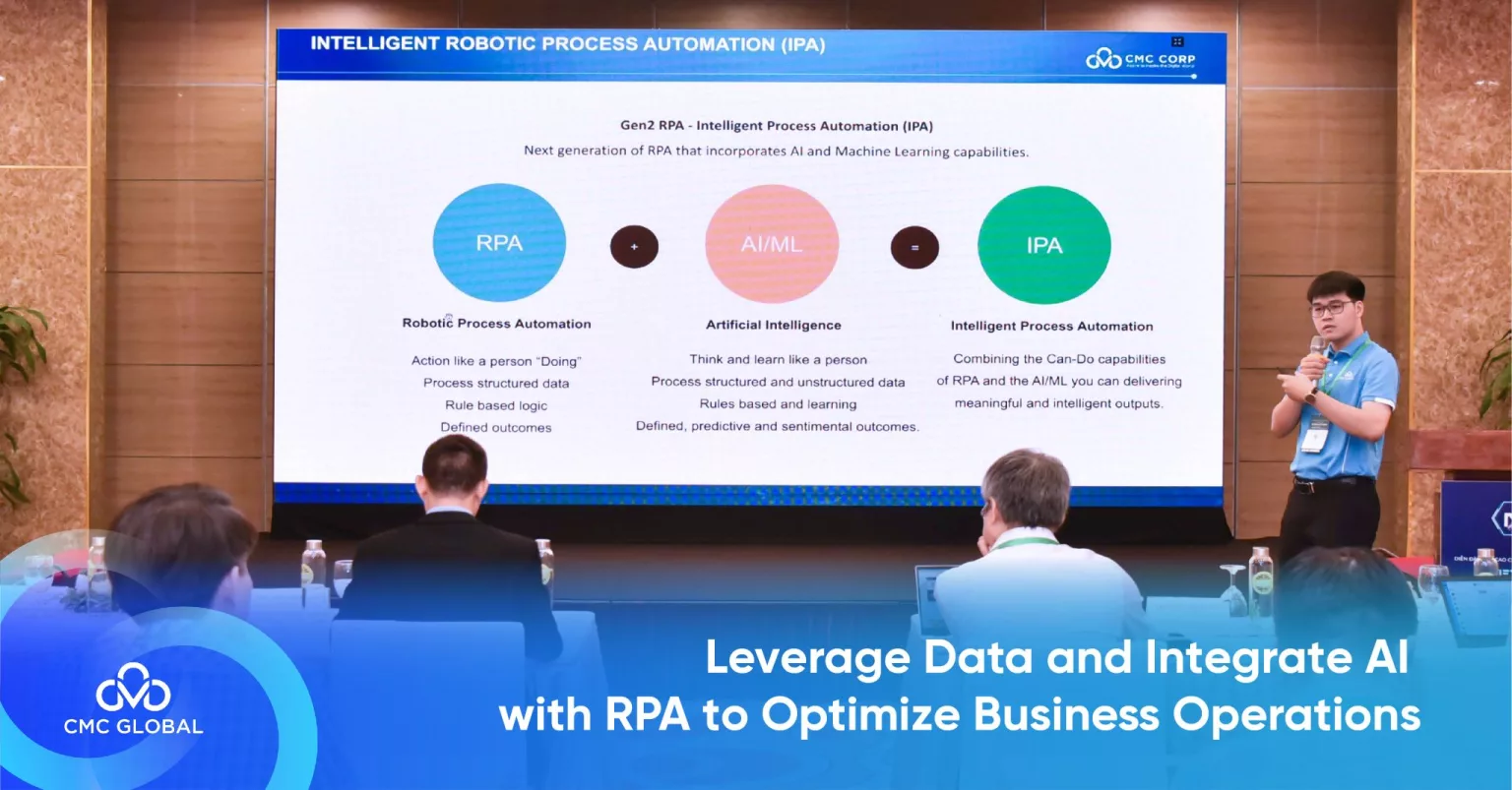

This is where CMC Global steps in. Asia’s AI advantage depends on accessible technology, and we bridge the gap between advanced AI and everyday factory floors.

How CMC Global Helps Asia’s Top Manufacturers Shine with AI

#1 Making AI Simple for Everyone

CMC Global is making AI easy for all factory workers. With no-code and low-code platforms, anyone—from line workers to managers—can use AI tools, like spotting product flaws instantly, without needing tech skills. This opens up AI’s power to everyone, making factories work better and faster.

#2 Hybrid Cloud: Powering AI Growth

CMC Global’s hybrid cloud systems keep AI running smoothly. They handle data and AI tools, helping factories of all sizes grow easily. Whether it’s a small shop or a huge plant, this setup makes sure AI can keep up with changes in the industry.

#3 Training Workers and Building AI Readiness

Switching to AI means changing how people work, and CMC Global makes it smooth. Their training programs teach workers how to use AI and automation with confidence. They also help factories get excited about AI, reducing worries and building support. This people-first approach makes AI a natural part of every factory’s day.

The Bottom Line

AI is taking Asian manufacturing to new levels, making factories more efficient, saving money, and sparking new ideas. The success of smart factories, like a top Japan automaker’s AI-powered EV plant, shows what’s possible: a 30% smaller workforce, faster production, and ideas that help factories worldwide.

Ready to Transform Your Manufacturing with AI?

👉 Join CMC Global at the AHK Tech Design Roadshow (May 19–23th, Germany) to explore cutting-edge AI solutions for efficiency, quality control, and predictive maintenance.

👉 Meet our CTO, Mr. Tu Dang, and discover how Vietnam’s top tech talent can accelerate your AI adoption.

📅 Limited seats available! Register now or contact Gina Nguyen at [email protected] for more information.